| Engine Oil Treatment | Engine Oil Treatment - Heavy Equipment | Add To My Cart | Send A Message | Have An EngeneRx Story? Send Us Photos! |

Engine Oil Treatment For Heavy Equipment

| Engine Oil Treatment | Engine Oil Treatment - Heavy Equipment | Add To My Cart | Send A Message | Have An EngeneRx Story? Send Us Photos! |

Engine Oil Treatment | Engine Oil Treatment For Heavy Equipment

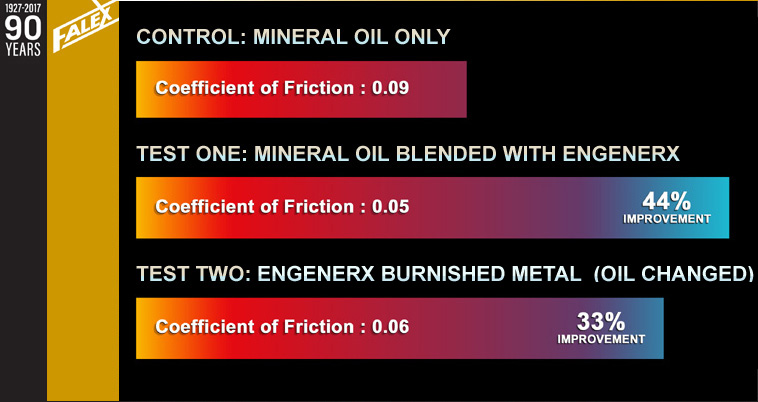

30+ Years of Battle Proven Technology Our advanced solid particle technology has a 30+ year proven track record with the United States military and the Aerospace industry. During these same three decades, the "snake oil" persona of the engine additive industry has been marred by a plethora of companies that have enriched themselves by making misleading, highly inflated and outright false claims about their products capabilities. We are fully aware of this skepticism. Here is an honest portrayal of what our product's technology can do for you, and why you should consider making EngeneRx an integral part of your vehicles regular maintenance. Falex Four Ball Test Results Your Preferred Motor Oil Can Be Improved! Engine Oil Treatment Made With Battle Proven Technology The lubrication requirement of an internal combustion engine is far less demanding than the high cyclic weapons used by the United States military. Our Advanced Solid Particle Lubricate Technology allows for the continuous fire of high cyclic weapons in the worst possible environments. Our micronized suspension of chemically charged particles will harmoniously blend with your preferred engine oil to improve performance and dramatically reduce friction and wear. The United States Military, the Aerospace industry and your engine will share a common bond: EngeneRx Lubri+Can© Advanced Solid Particle Technology. 8 fl oz of EngeneRx Engenerizes up to 24 quarts of your preferred mineral or synthetic motor oil.

Advanced Solid Particle Technology For Mineral and Synthetic Oil | EngeneRx Engine Oil Additive

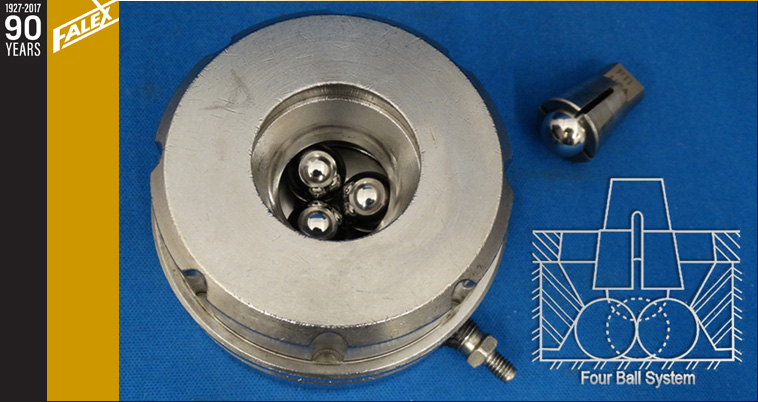

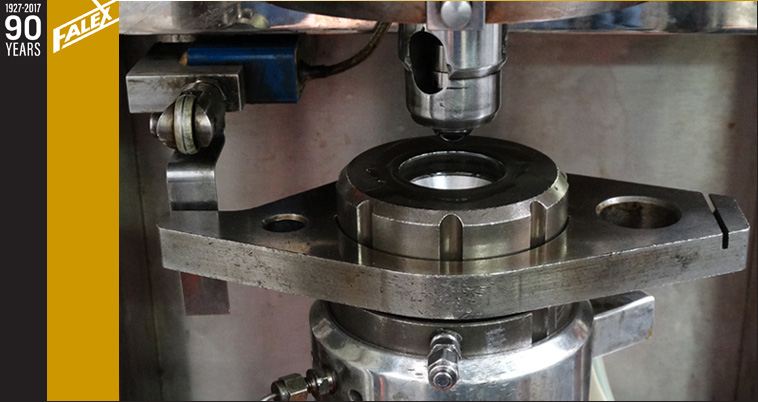

The four ball test is an industry standard. You need to understand, the four ball test cannot duplicate the heat and intense pressure produced by an internal combustion engine.

The four ball does substantiate our claim that the micronized, positively charged solid particles are effectively burnished into the metal --which significantly reduces friction and wear.